現代工廠採用鈑金加工來製造堅固精密的零件。這種方法是製造業的關鍵,有助於快速輕鬆地創建詳細設計。

看看事實。 2024年,全球鈑金市場規模為35億美元。預計到2033年,該市場將成長至58億美元,年均成長率為6.1%。這顯示鈑金在汽車、飛機和建築等行業中的重要性。例如,製造輕量化電動車需要先進的鈑金來打造堅固而輕巧的零件。此外,城市數量的增加意味著對優質建築材料(例如屋頂和框架)的需求也會增加。

鈑金加工有助於滿足這些需求,同時保持精度和高品質。在當今快速變化的製造業中,鈑金加工是必不可少的。

關鍵要點

鈑金加工對於製造堅固、精密的零件至關重要。它對汽車、飛機和建築等行業都有幫助。

主要方法包括切割、成型、連接和精加工。每種方法都可以提高速度和產品品質。

機器和智慧工具使工作更快、更準確。這既節省了成本,也有利於保護環境。

拋光、噴漆和塗層等精加工步驟可延長零件的使用壽命,還能提升零件的外觀,並符合更高的標準。

回收和節能等環保做法可以減少浪費。這些做法有助於製造業更好地造福地球。

鈑金加工關鍵技術

鈑金加工採用多種方法將平板變成有用的零件。這些技術有助於提高製造的精準度、速度和靈活性。讓我們來看看主要的方法。

切割方法(雷射切割、等離子切割、水刀切割)

切割是金屬板材加工的第一步。它將大塊板材切割成更小、可用的小塊。雷射切割非常精準快速。它使用聚焦的雷射光束切割材料,幾乎不產生浪費。這種方法非常適合精細的設計和圖案。等離子切割使用熱等離子弧來切割較厚的材料。它比雷射切割速度更快,但精準度較低。水刀切割使用混合有磨料的高壓水。它避免了熱損傷,非常適合熱敏材料。

主要優勢:

雷射切割精確、快速且減少浪費。

等離子切割適用於切割厚材料,而且價格便宜。

水刀切割可避免熱損傷並可處理多種材料。

新技術使這些方法更加完善、精確。例如,雷射切割因其先進的功能而成為目前最受歡迎的選擇。

成型製程(彎曲、液壓成型、沖壓)

無需去除任何材料即可對金屬板進行成型。折彎工藝簡單,使用折彎機將板材折彎成一定角度。沖壓製程使用模具將板材壓成一定形狀。沖壓工藝快速且穩定,非常適合大規模生產。

液壓成形是一種更先進的成形方法。它使用高壓流體來製造複雜的形狀。此工藝可製造出重量輕但強度高的零件。例如,液壓成形在汽車中用於製造A柱和橫樑等零件。這些部件更輕、更堅固,從而提高了汽車性能。

液壓成形與CNC工具機配合使用效果更佳,精度更高。這使其成為需要堅固輕量化零件的行業的首選。

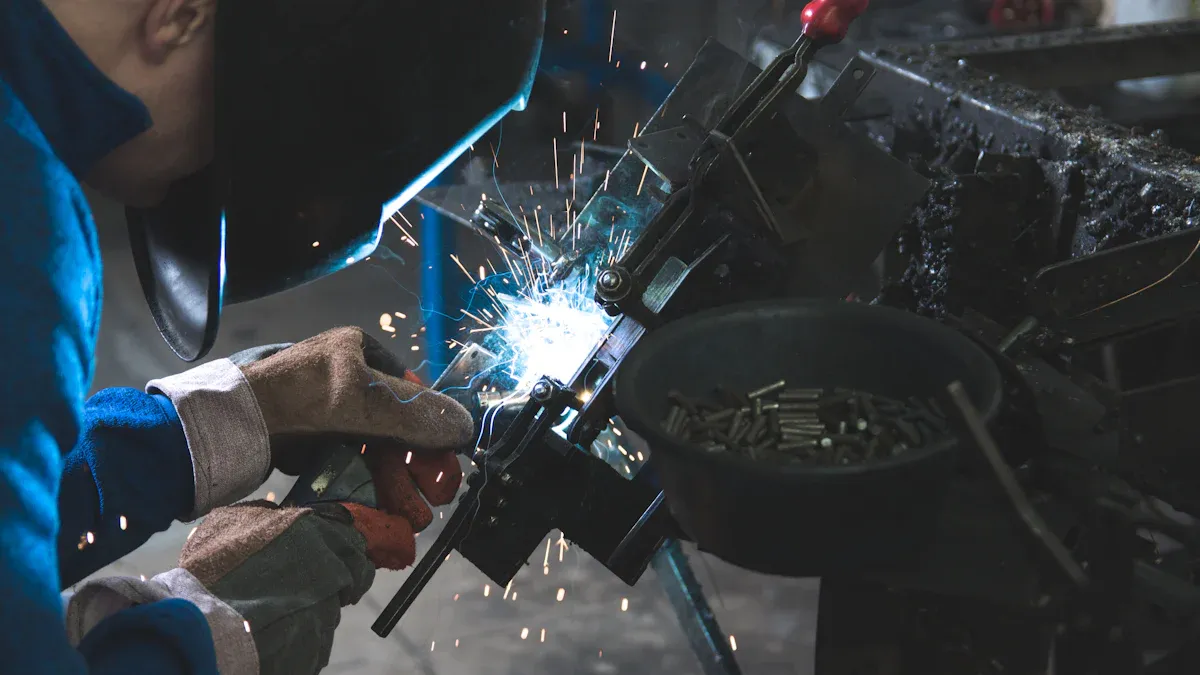

連接技術(焊接、鉚接、黏接)

切割和成型後,連接方法將金屬板部件連接起來。焊接是常見的連接方法,利用熱量將金屬連接起來,形成牢固的結合。鉚接使用緊固件連接無法焊接的零件。膠黏連接使用膠水連接材料。它適用於輕質部件和不耐熱的材料。

主要優點:

焊接可以形成堅固且持久的接頭。

鉚接適用於無法焊接的材料。

黏合劑黏合非常適合輕質、熱敏感的零件。

自動化改進了這些方法。機器人和機器使連接更加精確和高效。這節省了成本並提高了產量,使這些技術成為現代製造業不可或缺的要素。

精加工製程(拋光、塗層、陽極處理)

精加工製程對於鈑金零件的品質至關重要。這些方法可以改善零件的外觀並保護其免受損壞。三種常見的精加工方法是拋光、塗層和陽極處理。

拋光

拋光使金屬表面光滑有光澤。它可以去除刮痕、粗糙點和瑕疵。這個過程可以讓零件保持美觀和清潔。拋光錶面非常適合電子產品或裝飾品等物品。

拋光還能增強零件的強度。光滑的表面可以防止污垢和水造成生鏽。沖壓後進行拋光,確保產品品質優良、經久耐用。

塗層

塗層是在金屬表面添加一層保護層。這層保護層可以是油漆、粉末或其他材料。塗層可防止生鏽、抵禦化學物質侵蝕,並使零件外觀更佳。例如,汽車零件上塗有塗層是為了應對惡劣天氣。

塗層類型取決於特定用途。有些塗層能夠耐熱,有些則能增加顏色或光澤。塗層非常適合沖壓件,能夠保持其強度和美觀。

陽極處理

陽極氧化是一種特殊的鋁材處理過程。它會在鋁材表面形成一層堅固的保護層,防止生鏽,並增強金屬的硬度。航空航太和電子等行業會使用陽極氧化製程來製造輕質、堅固的零件。

陽極氧化零件經久耐用,抗損壞能力更強。這種工藝非常適合提升產品的耐用性。例如,手機中的陽極氧化鋁材質既堅固又時尚。

提示:為您的專案選擇合適的表面處理流程。拋光最美觀,塗層保護效果好,陽極氧化最適合鋁材。

精加工工藝的好處

拋光、塗層和陽極氧化等精加工方法有許多優點:

它們可以防止生鏽,延長金屬零件的使用壽命。

它們使零件更加堅硬且不易磨損。

他們修復並保護舊部件,幫助它們延長使用壽命。

陽極氧化使鋁具有額外的強度和保護性。

使用這些精加工方法可確保您的金屬板專案堅固且持久。

鈑金在製造業的應用

鈑金是製造許多行業零件的關鍵材料。其強度和柔韌性使其成為製造高品質零件的理想材料。讓我們看看它如何助力三大領域。

汽車零件(車身面板、底盤零件)

鈑金是車身面板和底盤零件的關鍵。這些部件需要堅固耐用,並完美貼合以確保安全。數控工具機有助於為這些零件打造精準的設計,確保每個零件都能完美貼合汽車結構。

為了確保高品質,各公司嚴格遵循ISO 9001:2015等標準。他們也會使用超音波和滲透探傷等檢測手段來檢查是否有問題。像Foxsen這樣值得信賴的供應商,能夠提供優質材料,製造安全耐用的汽車零件。

鈑金在許多方面改善了汽車:

更輕的零件可以節省燃料並延長電動車的行駛里程。

更快的生產速度可以跟上新車的設計。

這些改進顯示了金屬板如何幫助汽車製造業發展。

航空航太結構(飛機蒙皮、引擎部件)

航空航太領域使用金屬板材製造堅固輕巧的零件。飛機蒙皮和引擎零件必須承受嚴苛的工況,同時保持輕量化。液壓成形和沖壓技術能夠以高精度製造複雜形狀,並滿足嚴格的標準。

陽極氧化使鋁零件更加堅固,並防止生鏽。這項製程有助於延長零件(例如飛機機身)的使用壽命,減少維修次數並提升效能。

環保也很重要。鈑金生產可以減少浪費並節省能源。這有助於實現綠色目標,例如製造節油引擎。它有助於航空航太業減少碳足跡。

建築材料(屋頂、暖通空調系統)

在建築領域,金屬板材是堅固耐用的材料。屋頂板和暖通空調系統就是常見的例子。這些產品必須能夠抵禦惡劣天氣並經久耐用。粉末塗料等塗層可以防止金屬生鏽,並改善其外觀。

像SMART這樣的組織每年花費數百萬美元用於工人培訓。根據《國家學徒法》制定的計畫為工人學習新技能提供了清晰的途徑。這些項目不僅傳授技術知識,還提供長期的職業發展機會。

你知道嗎?超過一半的製造錯誤都是由於材料選擇不當造成的。教會工人選擇正確的材料可以減少這些錯誤。

投資培訓有助於工人掌握液壓成形和沖壓等新工具。這不僅能提高效率,還能讓您的企業應對未來的挑戰。

人工智慧和機器人技術的新趨勢

人工智慧和機器人正在改變金屬板的製造方式。這些工具使工作更聰明、更快捷、更有效率。工廠現在可以更輕鬆地生產出更優質的零件。

人工智慧和機器人技術的重要趨勢

人工智慧品質檢查

鈑金加工將扁平的金屬板材加工成實用的物品。它採用切割、成型、連接和精加工等工藝。這些工序為汽車、飛機和建築物製造出堅固精密的零件。

雷射切割與等離子切割有何不同?

雷射切割使用雷射光束進行整齊細緻的切割。它浪費更少的材料,並且非常適合精細的設計。等離子切割使用高溫等離子,可以快速切割厚金屬,但精度較低。每種方法都適用於不同的任務。

為什麼在製造業使用液壓成形?

液壓成形利用高壓流體製造堅固、輕巧的零件。它可以塑造複雜的設計並節省材料。這種方法因其精確高效而在汽車和飛機製造中很常見。

金屬板可以重複使用嗎?

是的,金屬板很容易回收。舊零件可以熔化後製成新零件,且品質不會降低。回收有助於節約資源、減少浪費,並支持綠色製造。

哪些行業最常使用鈑金加工?

汽車、飛機、建築和電子業都依賴金屬板材。金屬板材可以製造現代產品所需的堅固、輕巧且客製化的零件。

Modern sheet metal methods save money and materials. Using thinner sheets keeps products strong but costs less. "Think thin" ideas cut material use by 20% and energy by 70%.

These eco-friendly ways also boost profits. For example, hydroforming makes light but strong parts. This reduces waste and saves energy. These methods help both the planet and your budget.

Integration of Automation and Smart Technologies

Automation and smart tools make sheet metal work faster and better. Machines track their own performance to stay efficient. Automated systems adjust settings for perfect results during forming.

Smart tools predict when machines need fixing, avoiding breakdowns. IoT lets machines change based on real-time needs, saving resources. Tracking tools like OEE measure how well machines work, helping improve processes.

Better systems mean fewer delays and smarter choices. Automation speeds up production, meeting deadlines without losing quality. These tools make sheet metal processing a key part of modern manufacturing progress.

Sustainability and Eco-Friendly Practices

Sustainability is very important in manufacturing today. Sheet metal processing helps create greener solutions for the planet. Using eco-friendly methods reduces waste, saves energy, and protects nature.

Reducing Material Waste

Advanced methods like laser cutting and hydroforming cut down waste. These techniques use every piece of metal efficiently. For example, laser cutting makes exact shapes with little leftover scrap. This saves materials and lowers costs.

Did You Know? Smart material use can cut waste by 30%, making manufacturing greener.

Energy Efficiency

Modern machines use less energy during sheet metal processing. CNC technology helps machines work only when needed. This saves power and reduces pollution. Lightweight metal parts, like those in electric cars, also improve energy use.

Recycling and Reusability

Sheet metal can be recycled easily. Old or unused parts are melted and reused without losing quality. Recycling cuts the need for new materials and reduces mining pollution.

Supporting Green Goals

Using sustainable sheet metal practices supports global climate efforts. Many companies earn eco-friendly certifications like ISO 14001. These show care for the environment and attract green-minded customers.

Tip: Start by recycling scrap metal and using energy-saving machines. Small steps lead to big changes.

Eco-friendly sheet metal processing helps both the planet and businesses. It’s a smart way to succeed while protecting the Earth.

Challenges and Future Trends in Sheet Metal Processing

Overcoming Material Limitations

Working with sheet metal can be tricky due to material issues. If you ignore how metals behave, parts may crack or tear. Picking the wrong metal can make parts weak or unsuitable for certain uses.

Tiny flaws in sheet metal are another problem. These defects are hard to see with regular tools but can weaken the structure. For example, large sheets need many cameras to check for flaws. Shiny surfaces cause glare, making it harder to spot problems. Fast production lines also make manual checks difficult, leading to more mistakes.

Different metal thicknesses bring their own challenges. Thin sheets under 1 mm can bend or warp easily. Very thin sheets cost more to process. Sheets between 1-6 mm are harder to work with and cost more too. Solving these problems needs better inspection tools and flexible solutions.

Tip: Always check the metal's thickness and properties before starting. This saves materials and improves results.

Adapting to Technological Advancements

The sheet metal industry is changing fast with new technology. Methods like hydroforming, laser cutting, and 3D printing make work faster and more accurate. These tools help create complex shapes and save time without needing special molds.

Customers now want unique designs and smaller orders. Using flexible manufacturing methods helps meet these demands while keeping quality high. Being eco-friendly is also important. Machines that use less energy and recyclable materials help protect the environment and meet industry rules.

Automation and AI are making sheet metal work smarter. Machines with IoT can adjust settings instantly for better results. These tools improve tasks like stamping and hydroforming, making them easier and more reliable.

Workforce Training and Skill Development

New technology means workers need better skills to use modern machines. Training programs help employees learn the latest tools and methods. Hands-on lessons from experts improve teamwork and problem-solving skills.

Groups like SMART spend millions each year on worker training. Programs under the National Apprenticeship Act give workers a clear path to learn new skills. These programs not only teach technical knowledge but also offer long-term career growth.

Did You Know? Over half of fabrication mistakes happen because of poor material choices. Teaching workers to pick the right materials can lower these errors.

Investing in training helps workers handle new tools like hydroforming and stamping. This boosts efficiency and prepares your business for future challenges.

New Trends in AI and Robotics

AI and robots are changing how sheet metal is made. These tools make work smarter, quicker, and more efficient. Factories can now produce better parts with less effort.

Important Trends in AI and Robotics

AI for Quality Checks

AI systems find flaws in sheet metal instantly. Cameras and sensors spot tiny defects people might miss. This ensures all parts are high-quality. AI also warns about problems early, saving money and time.Robots for Cutting and Forming

Robots do tasks like bending, stamping, and cutting. They are faster and more accurate than humans. For example, robotic arms with lasers can cut detailed shapes easily. This speeds up production and keeps results consistent.AI for Machine Maintenance

AI tools watch machines and predict when repairs are needed. This stops sudden breakdowns and keeps work on track. Fixing issues early saves both time and money.

Did You Know? AI can cut machine downtime by 30%, making factories more efficient.

How AI and Robotics Help Sheet Metal Work

AI and robots also allow custom designs. Machines can be programmed to make special parts for different projects. This helps meet customer needs and stay competitive.

Tip: Start small by using AI for quality checks or robots for simple jobs. Add more as you see success.

Using these tools keeps you ahead in today’s fast-paced manufacturing world. AI and robots make sheet metal work smarter, faster, and more dependable.

Sheet metal work is very important in today's manufacturing. It helps make accurate, fast, and creative parts for cars and planes. New trends show the sheet metal tools market is growing quickly. This is because of better machines and the need for lighter, energy-saving materials. Developing countries are using more sheet metal as they build factories. As technology improves, sheet metal will keep changing how things are made. It will meet the needs of a world that is always moving forward.

FAQ

What is sheet metal processing?

Sheet metal processing changes flat metal sheets into useful items. It uses methods like cutting, shaping, joining, and finishing. These steps make strong, exact parts for cars, planes, and buildings.

How is laser cutting different from plasma cutting?

Laser cutting uses a laser beam for neat, detailed cuts. It wastes less material and works well for fine designs. Plasma cutting uses hot plasma to cut thick metal fast but less precisely. Each method fits different tasks.

Why is hydroforming used in manufacturing?

Hydroforming makes strong, light parts with high-pressure fluid. It shapes complex designs and saves materials. This method is common in car and airplane making because it’s precise and efficient.

Can sheet metal be reused?

Yes, sheet metal can be recycled easily. Old parts are melted and made new without losing quality. Recycling helps save resources, cuts waste, and supports green manufacturing.

Which industries use sheet metal processing the most?

Car, airplane, building, and electronics industries depend on sheet metal. It makes strong, light, and custom parts needed for modern products.